YOU MAY FACE MORE RISK THAN YOU KNOW

When was the last time you verified the information on your calibration report? Using older instruments to calibrate your test equipment puts you at risk for lower accuracy. Or even worse, critical parameters may not be tested at all.

Data from 10 calibration service providers show all but one tested performance of less than 50% of the instrument’s specifications — in some cases, testing was less than 25%. If your tests rely on key critical specifications that are missed during calibration, your test equipment is likely out-of-specification. And you can no longer trust your test results. This uncertainty puts your reputation at enormous risk.

Application Note

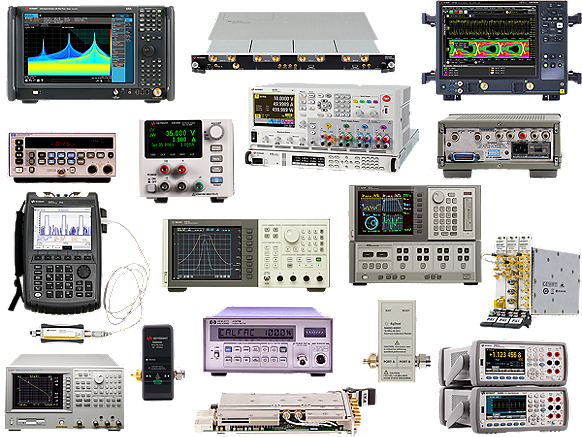

KEYSIGHT INSTRUMENT CALIBRATION

We measure every specification, every option, every time.

Choose the standard compliance to meet your test strategy

Select the right calibration for your Keysight instruments. Maybe you need measurement uncertainties, guardbanding, an accredited calibration, or a primary standards lab calibration. Alternatively, perhaps your calibration report needs to satisfy a particular ISO or ANSI metrology standard such as IS0 17025:2005 or ANSI Z540.3-2006. Keysight offers a wide range of calibrations to ensure you meet your requirements to your local and global needs.

All Keysight Service centers are accredited to their local accreditation body such as JCSS, CNAS, Poverka, UKAS, ANAB, and so many more.